yqgm@yongqiang-group.com ;sales@yongqiang-group.com

yqgm@yongqiang-group.com ;sales@yongqiang-group.com

yqgm@yongqiang-group.com ;sales@yongqiang-group.com

yqgm@yongqiang-group.com ;sales@yongqiang-group.com

1 High temperature resistance: Has good resistance to high temperature and fatigue, and remains undisturbed under high strength and high temperature conditions.

2 High quality: Exquisite workmanship, bright surface and highlighting high-end quality.

3 Use of superior materials:The raw materials of the products are made of high-quality materials, which are superior in elasticity, wear-resistant and longer in life, practical and convenient, and the quality is guaranteed.

【Product name:】Mobilephone contact spring

【Product dimension:】0.1*2*4mm

【Material:】 BeCu

【Processing time:】20pcs/min

【Customer:】 CCP

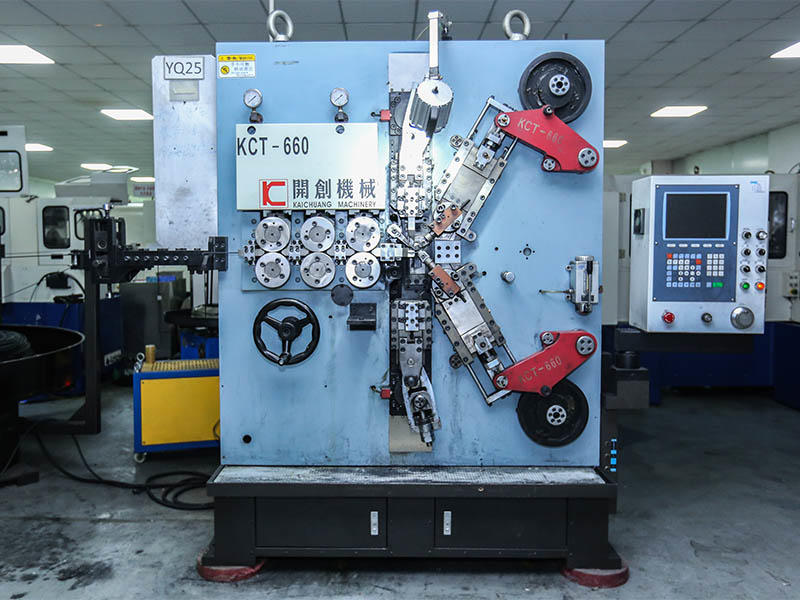

Our Factory

Valve Springs

|

Valve springs are among the most overworked and overstressed parts in your engine; yet, they are often the most overlooked components, too. Harmonics or high frequency fatigue is present in all racing engines and will usually destroy the valvetrain if not controlled. Properly designed valve springs will control the dominant harmonics, provide the needed stability, and reduce valvetrain component wear. We design valve springs for all forms of applications as well as springs in fuel injectors, latch mechanisms for valvetrain components, springs in torque converters, and clutch assemblies.

Design and Engineering of Valve Springs

Yisen’s engineers are fully experienced in product design, spring design analysis, dynamic simulation, and the application of advanced technology to produce innovation. We use a variety of software for spring design, modeling and assembly, and FEA to optimize performance. The latest improvements are on: advanced high tensile materials, nitriding and piece hardening, ovate and multi-arc wire sections, Beehive spring configuration, and advanced surface-finishing processes.

Please Click Here contact us to receive an estimate on OEM orders.

Our valve springs are computer designed to ensure that wire stress levels do not overpass the limits of stress defined in the diagrams of fatigue. We also utilize computer software that allows us to ensure that the harmonics are under control. This combined with our high quality steel alloy enables Yisen valve springs to be more durable in extreme conditions, giving your performance racing engine a serious competitive advantage in both performance and durability.

Summit Racing has single, dual, triple, beehive, and conical valve springs to meet your engine’s demands—no matter how high the rpm or lift!

Copyright © 2018 Dongguan Yongqiang spring hardware Co.,Ltd. | All Rights Reserved Design